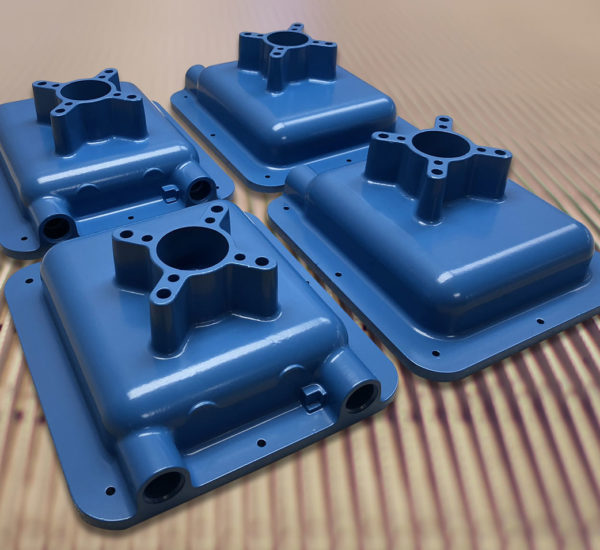

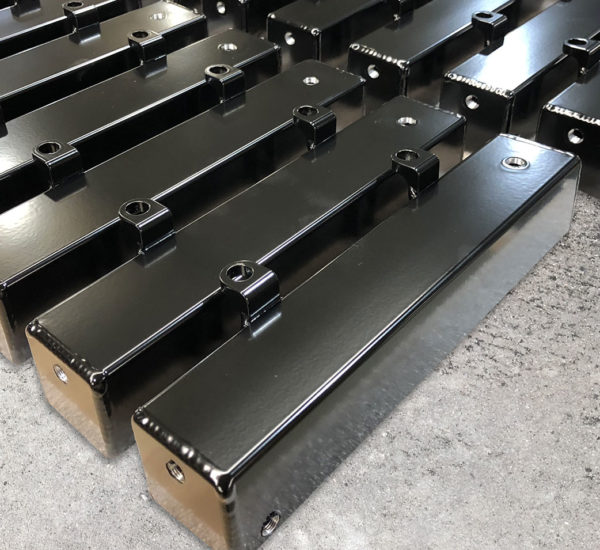

Rapid Finishing offers both screen printing and pad printing. Screen printing has the ability to thoroughly cover the substrate it is applied to and is an ideal solution applied to a flatter surface that requires a sharp and refined image or logo. Pad printing is ideal for three-dimensional or unusually-shaped parts and is ideal for adding thing like identification on parts produced in larger volumes.

SCREEN AND PAD PRINTING

Complete Screen and Pad Printing Capabilities

CAPABILITIES

Rapid Finishing can help you determine whether screen or pad printing is ideal for your project. Our services include artwork production, silk screen creation, printing make ready and application, oven bake or air-dry screening, quality inspection, packaging and shipment.

INDUSTRIES

Rapid Finishing has worked with a wide range of industries, including military contractors, automotive manufacturers, state lottery commissions, metal fabricating, food packaging, metal casting, public utilities, and local and national municipalities.

ADVANTAGES

Screen printing is fairly versatile and a variety of colors can be used on many different substrates. The screened image can be scaled in size to accommodate larger projects. It is also less expensive with lower tooling and setup costs. Pad printing, on the other hand, can print on curved surfaces and offers superior quality on textured surfaces.